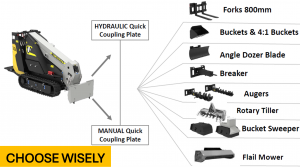

Look, you invested in a stand on loader for a reason. They’re nimble, surprisingly powerful, and give you an unmatched view of the job. But let’s be honest, the machine itself is only half the story. The real secret to boosting your capability and your bottom line lies in the skid steer loader attachments you pair it with.

Your Loader Is Only As Good As Its Attachments

Think of your stand on skid steer as the ultimate power tool handle. By itself, it can get you from A to B on site, but its true workhorse potential is only realised when you connect the right implement to its arms. The right set of attachments can essentially turn that single machine into an entire crew, ready to tackle just about any challenge you can throw its way.

This isn’t just about working harder; it’s about working smarter. Imagine not having to hire separate machines or call in different tradies for digging, demolition, or site clearing. You can do it all with the one loader you already own. It’s how you turn that initial purchase into a genuine profit-generating asset.

One Machine, Multiple Jobs

The standout feature of any stand on loader is its sheer versatility, and that comes directly from its attachments. In just a few minutes, a quick swap-out can completely change your machine’s purpose for the day.

- Morning Task: Kick things off with a 4-in-1 bucket, clearing out rubbish and levelling a patch of ground for a new concrete slab.

- Mid-day Job: Switch over to a trencher to carve out footings for a retaining wall or run some new irrigation lines.

- Afternoon Finish: Pop on a set of pallet forks to unload building materials from a delivery truck, staging everything for the next day’s work.

This ability to pivot between jobs without dragging more equipment to site is what makes these machines indispensable on any modern Australian worksite. It saves a massive amount of time, slashes operational costs, and keeps your project humming along without frustrating delays.

A machine sitting idle isn’t making you money. Having the right attachments on hand means your loader is always ready for the next paying task, whether it’s the main job or an extra service you can now offer your clients.

Built for a Universal Fit

One of the smartest things the industry has done is standardise around a universal mounting plate system. This is a huge win for operators because it means that quality attachments, like those for a Mechbadger, will often fit perfectly on other popular stand on brands. You aren’t trapped in a single manufacturer’s ecosystem.

For instance, that new auger drive you bought for your main loader can probably be hooked up to a hired Dingo, Kanga, or Toro if you need an extra machine for a big job or run a mixed fleet. This kind of flexibility gives you incredible freedom and protects your investment, ensuring the gear you buy today will serve you well for years. You just need to double-check the mounting plate and hydraulic specs, but these days, compatibility is the rule, not the exception.

A Tradie’s Guide to Attachment Types

Think of your loader as the ultimate power tool, and the attachments as its specialised bits. They’re not just lumps of steel; each one is engineered for a specific job. Getting your head around the main categories is the first step to building a truly versatile kit that pays for itself over and over.

Once you know what’s out there, your whole mindset shifts. You stop asking, “how on earth am I going to do that?” and start thinking, “which tool do I need for this?”. It’s all about matching the right attachment to the job in front of you. That’s what separates the pros from the amateurs and lets you pack more paying work into every day.

Earthmoving and Digging

This is the bread and butter for any stand on loader. These attachments are all about shifting dirt, digging holes, and getting the ground ready for whatever comes next. Honestly, they’re the foundation of any good attachment collection.

- Buckets: The most common attachment you’ll see, but they’re not all the same. A standard bucket is great for moving soil or mulch. The real game-changer, though, is the 4-in-1 bucket. It’s the Swiss Army knife of attachments – it can scoop, blade, grapple, and backfill, saving you a heap of time you’d otherwise spend swapping tools.

- Augers: Got to dig holes for fence posts, piers, or planting trees? An auger is your best mate. It drills clean, uniform holes way faster than you ever could with a post-hole digger and a sore back.

- Trenchers: For laying pipes, irrigation lines, or electrical conduits, a trencher is non-negotiable. It carves a perfect, narrow trench at a consistent depth, doing in minutes what would take a crew hours with shovels.

Demolition and Breaking

Sometimes, you’ve got to break things before you can build something new. These heavy-duty attachments turn your nimble stand on loader into a pint-sized demolition machine, perfect for those tight-access jobs where a bigger machine just won’t fit.

A hydraulic hammer is a classic example. It’s an absolute beast for smashing up old concrete driveways, footpaths, or stubborn rock ledges that are in your way. For bigger jobs, a concrete cutter attachment slices through slabs with precision, while a rock crusher can turn demolition waste into usable aggregate right on site. They save your back and get the site cleared in a fraction of the time.

These powerful tools are often what separates a small-time operator from a contractor who can take on bigger, more profitable demolition and renovation projects. They expand your service offering significantly.

Material Handling and Cleanup

Once you’ve dug it up or knocked it down, you’ve got to move it. This is where material handling attachments come in, letting you lift, carry, and sort materials safely and efficiently. It’s where your loader’s power and stability really come into their own.

- Pallet Forks: An absolute must-have for any site that gets deliveries. Unload trucks, shift pallets of bricks, or move bulky items with no fuss. They basically turn your loader into a go-anywhere forklift.

- Grapples: A rock grapple is perfect for clearing scrub, rocks, and other awkward debris. For handling green waste or demo rubbish, a root grapple lets you get a secure grip on big, uneven loads.

- Brooms and Sweepers: To leave a job looking truly professional, a powered broom is brilliant. It cleans up dust, dirt, and small debris from driveways, car parks, and work sites, giving you that clean finish clients love.

To give you a quick cheat sheet, here’s a table matching some of the most common attachments to their jobs.

Common Stand On Loader Attachments and Their Jobs

| Attachment Category | Example Attachments | Primary Job Application |

| Earthmoving & Digging | 4-in-1 Bucket, Auger, Trencher | Moving soil, digging post holes, creating trenches for services. |

| Demolition & Breaking | Hydraulic Hammer, Concrete Saw, Rock Crusher | Breaking up concrete, rock, and other hard materials. |

| Material Handling | Pallet Forks, Grapple Bucket | Lifting pallets, moving logs, clearing site debris. |

| Ground Preparation | Spreader Bar, Ripper, Rotary Hoe | Levelling ground, breaking up compacted soil, tilling garden beds. |

| Cleanup | Sweeper/Broom, Dozer Blade | Cleaning hard surfaces, pushing and levelling loose material. |

Having this basic knowledge is a fantastic start. Getting familiar with these main categories gives you a mental map, helping you build an arsenal of tools that can tackle just about any task, on any site. For a deeper dive, you can learn how to master your attachments and really get the most value out of your mini loader.

Ensuring Your Attachments Fit Your Loader

There’s nothing more frustrating than getting a new piece of gear back to the site, only to discover it doesn’t fit your machine. It’s a costly and completely avoidable headache. Getting the compatibility right from the start is crucial, and luckily, it’s a lot simpler than you might think once you know what to look for.

The two main things you need to check are the mounting plate and the hydraulics. Get these two right, and you’ll be in business. Ignore them, and you’ll have a very expensive paperweight on your hands.

The Universal Mounting Plate Advantage

Years ago, matching an attachment to a loader could be a real nightmare. Every brand seemed to have its own proprietary system, which made life difficult for everyone. Thankfully, the industry got smart and moved towards a standardised system – a massive win for everyone on the tools.

Most modern stand on loaders use a universal mounting plate. This means you’re not locked into one brand. That quality rock crusher or concrete cutter you’ve had your eye on will likely connect to a whole range of machines without any drama, whether it’s a Mechbadger, Dingo, Kanga, or another brand.

This flexibility is a huge advantage for your business. It means you can:

- Share attachments across a mixed fleet: If you run a Mechbadger alongside another brand, you can often use the same attachments on all of them.

- Hire with confidence: Need to hire an extra machine for a big job? You can bring your own trusted attachments and know they’ll likely connect right up.

- Improve resale value: When you decide to sell your attachments, they’ll appeal to a much wider market of buyers, not just those who own the same loader as you.

The bottom line is that a universal mounting plate gives you freedom. It lets you buy the best attachment for the job, regardless of who made it, knowing it will work with the machine you already own. It’s a simple feature that saves a heap of trouble.

Matching Your Hydraulics

The second critical check is matching the hydraulic flow. Just like you wouldn’t put diesel in a petrol engine, you can’t run a high-demand attachment on a low-flow system.

Every powered skid steer loader attachment has a required flow rate, measured in litres per minute (LPM). Your stand-on loader has a specific hydraulic output, also measured in LPM. For everything to work properly, these two numbers have to be a good match.

It’s like using a pressure washer at home. If you connect a massive industrial spray wand to a small home-use pressure washer, you’ll just get a pathetic trickle of water. The pump simply can’t supply enough flow to make it work. It’s the exact same principle with your loader and its attachments.

High Flow Versus Standard Flow

Understanding the difference between high flow and standard flow is key to getting the right performance from your gear.

- Standard Flow: This is what most stand-on loaders come with. It’s perfect for the majority of attachments that require intermittent power, like a 4-in-1 bucket, pallet forks, or an auger.

- High Flow: This is a more powerful hydraulic system designed for attachments that need continuous, heavy-duty power. Power-hungry tools like large rock crushers, stump grinders, and profilers absolutely need a high-flow system to operate effectively.

Before buying any powered attachment, check its LPM requirement and compare it to your loader’s specs in the manual. Running a high-flow attachment on a standard-flow machine will lead to poor performance and could even damage the attachment’s hydraulic motor over time. This simple check ensures your new tool runs at full strength from the moment you connect it.

Technology is also making this easier. The integration of telematics and machine intelligence systems has started to change how operators monitor their gear, offering real-time data on performance and operational efficiency. This technology is gaining ground in Australia, partly due to the demands of mining and construction for tougher safety and efficiency standards. Alongside this, electric skid steer models are emerging to meet regulations for lower emissions and a growing demand for sustainability on site. To learn more about these industry shifts, you can explore the latest research on the skid steer loader market.

Attachments That Make You More Money

Let’s get down to brass tacks. Your stand-on skid steer is a solid investment, but the machine itself doesn’t make you money—it’s the work that does. The fastest way to boost your bottom line is to fit it out with skid steer loader attachments that either let you offer new, high-value services or make your current jobs run a whole lot smoother. It’s all about return on investment.

A smart attachment purchase isn’t just another cost; it’s a tool for generating more income. Instead of just shifting dirt, you could be crushing rock, cutting concrete, or installing fences, all with the same power unit. This is how you stop being just another bloke with a loader and start being the versatile contractor who can tackle a wider range of profitable jobs.

Game-Changing Attachments for Your Business

Some attachments are just pure money-makers. They solve expensive problems for your clients or save you an absolute fortune in time, labour, and materials. These are the tools that pay for themselves in no time and keep earning for you for years to come.

Take a mini rock crusher, for example. Instead of paying to haul away broken concrete and rubble, and then paying again to bring in fresh aggregate, you can crush it right there on-site. You’ve just turned a waste product into a valuable resource, potentially saving thousands on a single job. That kind of efficiency is a massive selling point for your clients.

Another high-value tool is a concrete cutter. Having the ability to precisely slice up a driveway or slab for repair work opens up a completely new income stream. It lets a small crew take on concrete jobs that might otherwise need specialised subcontractors, which means you keep more of the profit in your own pocket.

The best attachments are the ones that turn a single-function machine into a multi-purpose problem solver. They allow you to say “yes” to more types of work, which is the key to growing your business.

Versatility That Pays the Bills

While specialised tools like crushers are fantastic, never underestimate the earning power of pure versatility. An attachment that can do the work of four different tools is an efficiency machine, and in that department, nothing beats the 4-in-1 bucket. It’s a dozer, a grapple, a scraper, and a bucket all rolled into one.

Think about a typical site clean-up. With a 4-in-1, you can scrape the ground clean, grab and lift awkward debris like logs or broken concrete, level out soil, and load the truck—all without leaving the controls to swap implements. Every minute you save is a minute you can spend on the next paying task. This is one of the most practical ways to improve your on-site workflow. In fact, finding ways to boost your efficiency is a core part of running a successful operation, and you can find more tips on how to improve jobsite productivity in our guide.

Real-World Scenarios Where Attachments Shine

Let’s see how this plays out on a real job site.

- The Landscaper: A landscaper invests in an auger attachment. Suddenly, they aren’t just doing lawns and gardens anymore. They can now offer fence installation, a high-demand service that brings in great money. A job that once required back-breaking manual digging or hiring a specialist is now a quick and profitable add-on to their services.

- The Small Concreting Crew: A small crew adds a hydraulic breaker to their kit. Now, they can confidently bid on renovation jobs that involve smashing up old, thick concrete slabs. They can handle bigger demolition tasks without needing to bring in a larger excavator, which makes their quotes far more competitive.

Good quality attachments, whether for a Mechbadger or a competitor’s machine like a Dingo, are built tough. Durable gear means less downtime spent on repairs and more uptime earning money. When you invest in well-made steel, you’re investing directly in your business’s reliability and profitability.

Keeping Your Attachments in Top Nick

Your skid steer attachments are a significant investment, and like any quality tool, they need proper care to perform. A little routine maintenance is the difference between a reliable workhorse and an unexpected, costly breakdown. This isn’t about becoming a full-time mechanic; it’s about smart, preventative habits that keep your gear running smoothly and protect its long-term value.

Think of it this way: a well-maintained attachment isn’t just more dependable, it’s safer for everyone on site. Taking just five minutes at the start and end of each day for a quick inspection can save you weeks of downtime and thousands in repair bills. It’s a simple discipline that pays dividends.

The Daily Pre-Start Check

Before you even turn the key, make a quick walk-around part of your daily ritual. It’s a fast, simple check that spots minor issues before they escalate into major headaches.

- Inspect Hydraulic Hoses: Keep an eye out for any cracking, rubbing, or leaks. A tiny pinhole leak in a hydraulic line is a serious safety risk and can quickly lead to bigger problems.

- Check Fittings and Pins: Ensure all hydraulic fittings are snug and that locking pins and couplers are secure. You’d be surprised how often a loose connection is the root cause of a failure.

- Hit the Grease Points: A pump of grease into every specified nipple is the cheapest insurance you can buy. It keeps everything moving freely while pushing out the dirt and moisture that accelerate wear.

These few steps ensure your attachment is safe and ready to work every single time.

Weekly Checks and Proper Cleaning

Going beyond the daily check, a more detailed inspection once a week will keep your skid steer attachments in prime condition. This is particularly crucial for tools that deal with a lot of abrasive material.

For instance, regularly check the cutting edges on your buckets. A worn or chipped edge makes digging much harder, putting extra strain on both the attachment and the loader itself. The same principle applies to auger or trencher teeth; sharp teeth cut efficiently, while dull ones just burn fuel and slow you down.

One of the most critical yet often forgotten maintenance jobs is a proper clean-down. After working with materials like concrete, mud, or certain soils, always clean your attachments. Caked-on material can be surprisingly corrosive and can seize up moving parts if left to harden.

This focus on maintenance isn’t just for attachments; it improves the efficiency of all your site equipment. For example, the same meticulous approach applies to your compaction gear. To see how this works across different tools, have a look at our pro’s guide to vibration plate compactors and see how proper care makes a huge difference.

Ultimately, looking after your attachments comes down to respecting your investment. Equipment that is kept clean, greased, and stored correctly will not only perform better and last longer, but it will also command a much higher price when you decide to sell or upgrade. It’s that practical, professional approach that sets the best operators apart.

Walk onto almost any job site in Australia these days, and you’ll likely spot a stand-on skid steer zipping around. It’s no surprise they’re popping up everywhere, from tight inner-city builds to sprawling rural properties. They’re just so handy.

These machines can sneak into spaces bigger loaders wouldn’t dream of, and the operator gets a brilliant, unobstructed view of the attachment and the work area. For any Aussie tradie, that combination is gold.

But the real magic isn’t just the machine itself—it’s the incredible array of skid steer loader attachments you can stick on the front. One moment you’re digging precise trenches for a plumber, and the next you’re running a rock crusher to turn old demo concrete into recycled fill. This sheer versatility is why they’ve become a go-to for construction, landscaping, and even on the edges of mining operations where nimbleness is everything.

More Than Just a Machine, It’s a Business Opportunity

Think about it. With all the government money being pumped into housing and infrastructure projects, there’s a mountain of work out there perfectly suited for these compact powerhouses. Smart contractors are catching on fast. Owning one machine that can do the job of ten different pieces of equipment is a proven way to keep your business profitable and consistently busy.

The numbers back this up. The Australian skid steer loader market hit around $245 million in 2024 and is forecast to rocket up to nearly $314 million by 2030. This isn’t just some abstract figure; it’s a direct result of the everyday construction and civil jobs where these loaders shine. If you want to dig deeper into the data, you can read more about these market trends and see where the opportunities lie.

For a practical bloke on the tools, this trend means one thing: owning the right set of attachments puts you in a prime position to win more contracts and stay ahead of the pack.

Getting Ahead of the Competition

Staying competitive in this game isn’t just about putting in the long hours; it’s about working smarter. Having a solid toolkit of attachments means you can confidently say “yes” to a wider range of jobs without needing a whole fleet of specialised machines.

You can show up to a job and clear the site, dig the footings, shift the materials, and handle the final clean-up, all with the same stand-on loader. That’s efficiency.

Better yet, quality attachments are built to be interchangeable. For instance, the gear we supply for the Mechbadger is designed to a universal standard, which means it’ll often hook up perfectly to other popular stand-on loaders you might already have. This kind of compatibility lets you invest in top-tier tools—like a powerful concrete cutter or a heavy-duty grapple—knowing they’ll work with the machines you already own and trust. It’s that kind of strategic thinking that separates a good operator from a truly successful one.

Your Top Skid Steer Attachment Questions Answered

When you’re looking at attachments for your skid steer, especially for the popular stand-on models we see all over Australian worksites, a few questions always pop up. Let’s get them answered with some straight, practical advice.

Can I Use Any Brand of Attachment on My Loader?

In most cases, you absolutely can. The good news is that most modern stand-on skid steers, from the Mechbadger right through to other major brands, are designed with a universal mounting plate. This industry standard is a real game-changer, giving you the freedom to use a single attachment on different machines.

The real detail you need to watch is the hydraulics. Before you commit, you must check that your loader’s hydraulic flow rate—measured in litres per minute (LPM)—can meet the demands of the attachment. This is particularly crucial for powerful tools like a rock crusher or a concrete cutter. Always put the specs side-by-side before you buy or hire to avoid disappointment.

What’s the First Attachment I Should Buy?

If you’re starting your toolkit and can only choose one, make it the 4-in-1 bucket. No other attachment offers the same bang for your buck right out of the gate. It’s the ultimate all-rounder that massively boosts your machine’s capabilities without constant tool changes.

Think of it as the Swiss Army knife for your skid steer. You get a standard loading bucket, a grapple for shifting logs and debris, a dozer blade for levelling, and a clamshell for scraping or back-dragging. It’s easily the smartest first investment for anyone in landscaping, construction, or general site maintenance.

With this one attachment, your stand-on loader becomes a seriously versatile bit of kit from day one.

Do I Need High-Flow or Standard-Flow Attachments?

This really boils down to the specific tool you plan on using. The vast majority of everyday skid steer loader attachments—things like buckets, pallet forks, and standard augers—are perfectly happy running on a standard-flow hydraulic system.

You only need to think about a high-flow system when you’re dealing with the heavy hitters. These are the attachments that need a constant, powerful stream of hydraulic energy to perform, such as:

- Large profilers for roadworks.

- Heavy-duty stump grinders.

- Compact rock crushers.

Your loader’s manual will clearly state its hydraulic output (standard or high-flow), and every attachment will list its power requirements. Matching these two is non-negotiable; it’s the only way to ensure your gear performs as it should.

Ready to gear up your stand-on loader with attachments that are built to last? The team at Machtig Mobile Equipment sources and supplies premium European machinery and attachments designed specifically for tough Australian conditions. Find the right tool for the job by exploring our range.