When you're up against serious grime and need real muscle, nothing quite compares to the brute force of a diesel pressure cleaner. These machines are the heavyweights of the cleaning world, built for industrial-scale jobs where petrol and electric models just don't have the legs.

Why Diesel Pressure Cleaners Pack a Bigger Punch

Let's be honest. An electric pressure washer is perfect for sprucing up the deck chairs. A petrol unit is a solid step up, great for giving the driveway a once-over. But when you’re staring down caked-on mud on farm machinery, stripping baked-on grease from a workshop floor, or blasting grime off a mine site, you need to bring in the big guns. That’s diesel territory.

Think of it like this: an electric model is your family sedan, a petrol one is a dependable ute, but a diesel cleaner? That's the road train. It’s engineered for the massive, long-haul jobs where you simply can't afford to run out of steam.

Unpacking the Power: Torque and Longevity

The secret to a diesel engine’s sheer dominance lies in its torque. Petrol engines need to scream at high revs to hit their peak power, but a diesel engine generates immense torque at low, lazy RPMs. What does this mean for you? It means you get consistent, unwavering pressure that doesn’t falter or bog down, even when you're running it flat out all day.

It's this relentless, low-end grunt that lets it tear through the toughest muck without even breaking a sweat. For instance, if you're cleaning a grain harvester after weeks in the paddock, that low-revving power won't bog down when you hit a patch of thick, oily chaff. It just keeps ploughing through.

This low-revving nature also contributes to their legendary lifespan. Running cooler and with less internal stress than their high-strung petrol counterparts, diesel engines are simply built to last. This makes them the undisputed champion for anyone who needs a machine for daily, demanding work.

Diesel vs Petrol vs Electric: A Head-to-Head Look

Choosing the right pressure cleaner comes down to matching the machine to the job. This table cuts through the noise and gives you a straightforward look at where each type truly shines.

| Feature | Diesel Pressure Cleaner | Petrol Pressure Cleaner | Electric Pressure Cleaner |

|---|---|---|---|

| Best For | Heavy industrial, agricultural, and commercial cleaning. | Large domestic jobs, small commercial tasks, frequent use. | Light-duty home use, small patios, cars, and occasional tasks. |

| Power & Performance | Highest. Unmatched torque for extreme cleaning. | High. Good power for most tough jobs, but less torque. | Lowest. Suitable for general grime, struggles with caked-on dirt. |

| Portability | Good. Not tied to an outlet, but heavy. | Excellent. Fully portable and lighter than diesel models. | Limited. Tethered to a power cord, restricting range. |

| Runtime & Durability | Exceptional. Built for all-day operation and long life. | Good. Can run for hours but less durable than diesel. | Limited. Prone to overheating with prolonged, continuous use. |

| Upfront Cost | Highest. | Medium. | Lowest. |

Ultimately, while petrol and electric models have their place, diesel is in a class of its own for heavy-duty reliability and raw cleaning power.

A Real-World Scenario

Let's put this into perspective. Imagine you run an earthmoving company and need to clean a fleet of excavators at the end of a long, muddy week.

- An electric cleaner simply won’t have the grunt, and you'll be constantly fighting the limitation of a power cord.

- A petrol cleaner could probably handle one machine, but you might find it struggling under continuous, day-long use. Plus, the high-pitched engine noise can become seriously grating.

- A diesel pressure cleaner will just get to work. It’ll happily run all day, its low-end power effortlessly stripping away dried clay and grease, machine after machine. No fuss, no drama.

This is exactly why so many heavy industries across Australia depend on diesel. It’s a trend reflected in other equipment, too. The Australian market for diesel generators, valued at over $118 million in 2023, is growing precisely because industries need that same reliable, off-grid power. The demand for diesel pressure cleaners follows the same logic, providing robust, unstoppable performance for the toughest cleaning jobs. You can explore more about this trend in industrial equipment demand and see how it all connects.

Understanding PSI and LPM Without the Jargon

When you’re looking at diesel pressure cleaners, you'll see two numbers thrown around constantly: PSI and LPM. They might sound like technical waffle, but getting your head around them is the key to picking the right machine and getting the job done properly. Forget the textbook definitions; let's break it down in practical terms.

Think of it like this: PSI is the hammer, and LPM is the broom. You need both to clean up a big mess.

PSI is the Sledgehammer

PSI, or Pounds per Square Inch, is the raw, brute force of the water jet. It’s the sheer impact power that cracks, dislodges, and blasts away stubborn grime. A higher PSI means a more concentrated, powerful punch delivered to the surface.

Imagine you're trying to break up a thick slab of dried mud on an excavator track. You need a sledgehammer (high PSI) to smash that caked-on mess into smaller, manageable pieces. A regular claw hammer just won't cut it. This is what PSI does—it delivers the knockout blow to the toughest filth.

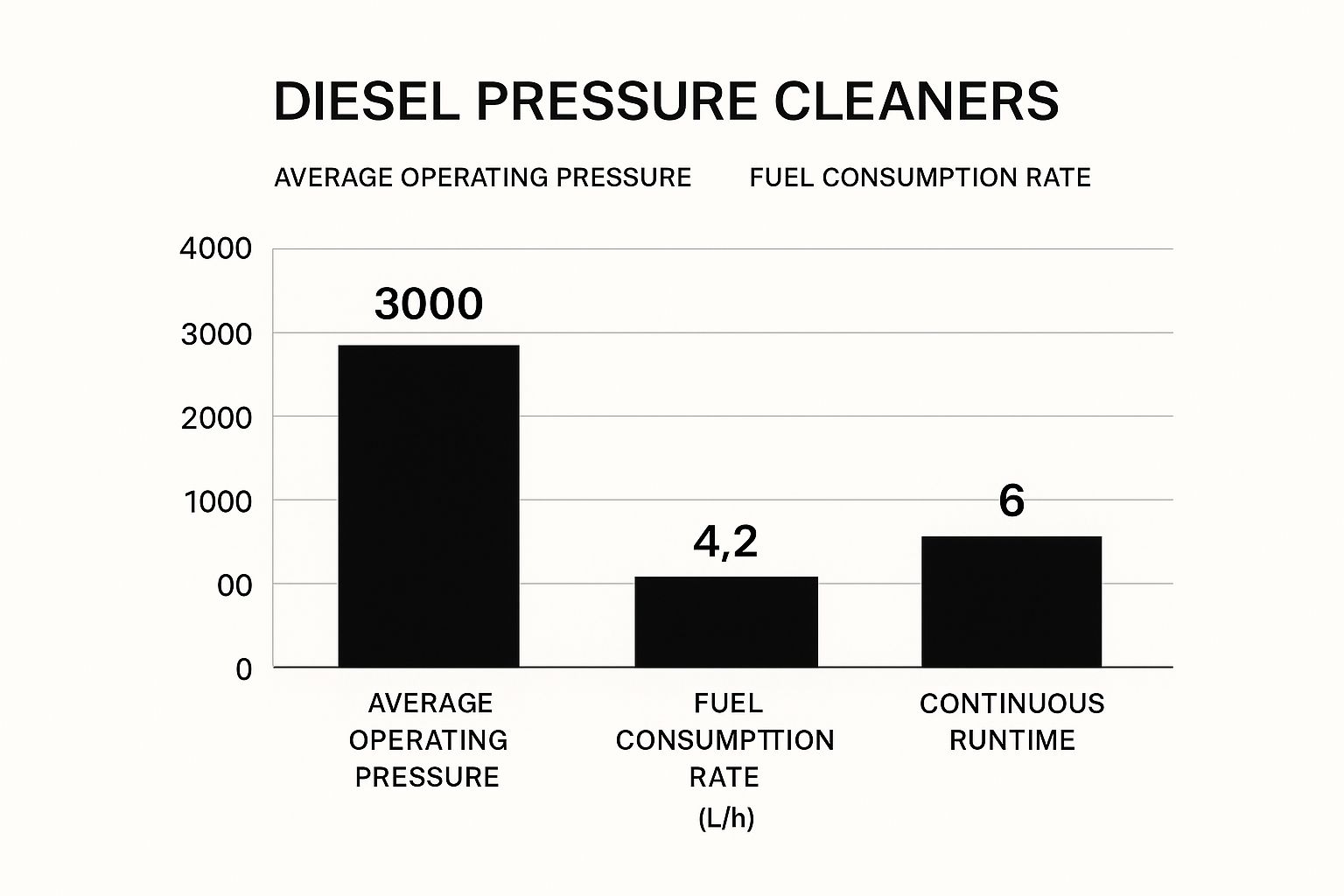

For really demanding jobs, like stripping old paint or blasting barnacles off a boat hull, you'll see machines pushing 3000 to 4000 PSI. This is the kind of force needed to break the bond between the grime and the surface itself.

LPM is the Big Sweeper

Now, what good is smashing up all that dirt if it just sits there? That’s where LPM, or Litres Per Minute, comes in. LPM is the flow rate of the water—think of it as the volume or the current that follows the hammer blow.

LPM is the big, wide broom that sweeps all the broken-up debris away, leaving a clean surface behind. A machine with high LPM can clear a larger area much faster because it’s moving more water. It’s the difference between using a garden hose to rinse a driveway and opening a fire hydrant.

A machine with high PSI but low LPM might be great at blasting a single stubborn spot, but it will take you forever to clean a large shed floor. You'll be drawing lines in the dirt instead of clearing it away efficiently. The real magic happens when you get the right balance of both.

Finding the Right Balance for the Job

Matching the PSI and LPM to your task is crucial. Using too much PSI can be like taking a sledgehammer to a plaster wall—you’ll do more harm than good. On the other hand, too little power means you’ll be there all day getting nowhere.

Here are a few practical examples of how you’d match the power to the job:

- Washing a Ute or Tractor: You don’t need extreme force here, as you risk stripping paint. A moderate PSI (1500-2000 PSI) is enough to dislodge mud, but you want a decent LPM (around 15 LPM) to rinse it all away quickly and efficiently.

- Cleaning a Concrete Workshop Floor: This is where you bring in more muscle. Oily, greasy stains require a higher PSI (around 3000) to lift them, and a solid LPM to flush the grime away, preventing it from just resettling somewhere else.

- Stripping Paint from Steel: This is a job for the heavyweights. You need maximum force, so you'd be looking for a diesel pressure cleaner with 4000 PSI or more to peel the paint off. The LPM helps clear the stripped flakes so you can see what you’re doing.

Understanding this balance is what separates a frustrating clean from a satisfying one. It ensures you have enough grunt to do the job right the first time without causing costly damage. It's about using the right tool for the job—and with diesel pressure cleaners, PSI and LPM are the two most important tools in your arsenal.

Choosing the Right Diesel Cleaner for Your Work

Picking the right diesel pressure cleaner is a bit like choosing a new ute—it needs to be the right fit for the jobs you actually do. A smart choice now gets you a reliable workhorse that pays for itself. The wrong one? It's just a machine that’ll give you grief down the track. This isn't about flashy sales talk; it's a practical guide to putting your money where it really counts.

Whether you're a farmer blasting mud off a harvester, a contractor cleaning up a building site, or a workshop owner keeping the floors spotless, the machine you choose matters. The small details, from the pump design right down to the quality of the wheels, are what separate the gear built for a long life from the stuff that just isn't.

This is a serious investment, and you’re not alone. The global demand for this kind of powerful equipment is on the rise. In fact, the market for fuel-driven high-pressure cleaners is projected to grow at a steady 5.0% compound annual growth rate through 2030. This highlights a worldwide need for efficient, heavy-duty cleaning solutions—a trend we're certainly seeing across Australia's demanding industries. You can learn more about the growth of the fuel-driven cleaner market and see why this gear is becoming essential.

Direct Drive vs Belt Drive: What’s the Difference?

When you start looking at the guts of a diesel pressure cleaner, the pump is its heart. And how that pump is connected to the engine makes a massive difference to its performance and lifespan. You'll generally come across two setups: direct drive and belt drive.

A direct-drive pump is bolted straight onto the engine's crankshaft. It's a simple, direct transfer of power. The pump spins at the exact same speed as the engine, which is usually around a screaming 3,000 RPM. It's a common design, but that high speed generates a lot of heat and vibration, leading to faster wear and tear on the pump's seals and bearings.

A belt-drive pump, on the other hand, is connected to the engine with a pulley and belt system. This setup allows the pump to run at a much slower, healthier speed—typically around 1,500 RPM. This slower pace means less heat, less vibration, and a much longer working life. If you're looking for a machine to use day in and day out, belt drive is the clear winner for longevity.

Think of it like this: a direct-drive pump is like sprinting everywhere you go. You get there fast, but you'll burn out quickly. A belt-drive pump is like jogging at a steady pace—it’s far more sustainable, and you can keep going for much, much longer.

Look for a Machine Built to Last

Beyond the pump, the overall build quality of diesel pressure cleaners is a dead giveaway of their true worth. A brilliant engine and pump are useless if the frame they’re sitting on is flimsy.

Here’s what to keep an eye on:

- A Solid Frame: Look for a heavy-gauge, fully-welded steel frame. A bolted-together frame will just rattle itself loose over time. It should also have a durable powder-coated finish to fight off rust and chipping.

- Quality Wheels: Don't overlook the wheels. You'll be dragging this heavy machine across some pretty rough ground, so you need large, pneumatic (air-filled) tyres. Those solid plastic wheels might be okay on a smooth workshop floor, but they’re a complete nightmare on a gravel yard or muddy site.

- A Reputable Engine: The engine is the guts of the whole operation. Stick with proven, reliable names like Yanmar or Kohler. These engines are known for their durability, good fuel economy, and the wide availability of spare parts and service.

- Good Quality Hoses and Fittings: Your machine is only as strong as its weakest link. Check for high-quality, steel-braided pressure hoses and solid brass fittings. Cheap hoses will burst under pressure and flimsy fittings will leak, leading to frustrating downtime on the job.

Investing in properly engineered gear isn't just about buying a product; it’s about ensuring reliability when you need it most. Just as you'd choose a trusted brand for your earthmoving gear, the same logic applies here. For instance, the quality compaction equipment from Batmatic demonstrates a commitment to durability that you should demand from all your heavy equipment. Choosing a well-built pressure cleaner ensures it will be a dependable asset for years to come.

Keeping Your Machine Running Like New

https://www.youtube.com/embed/6eqpczQpzig

A powerful diesel pressure cleaner is a serious investment, and just like your ute or any other piece of heavy kit, it needs a bit of looking after. Let's be honest, neglecting maintenance is the fastest way to turn a reliable workhorse into a costly headache. This isn't about becoming a mechanic overnight; it’s about simple, regular checks that stop big problems from ever starting.

Think of it this way: spending five minutes on checks before you fire it up is far better than losing a whole day of work because of a preventable breakdown. A little attention goes a long way, keeping your machine dependable and ready for any job you throw at it.

The Pre-Start Checklist: Do This Every Single Time

Before you even think about pulling that starter cord, get into the habit of this quick pre-start inspection. It's easily the most important maintenance you can do, and it takes less time than making a cup of coffee.

- Check the Engine Oil: Just like in your truck, the engine oil is everything. Pull out the dipstick, wipe it clean, pop it back in, and check the level. If it’s low, top it up with the right grade of oil specified in your manual. Running an engine on low oil is a one-way ticket to a seized motor.

- Inspect Fuel Levels and Filter: First, make sure you've got enough clean diesel to get the job done. More importantly, take a quick peek at the fuel filter bowl. If you see water or a heap of gunk in there, it’s time to drain and clean it out. Dirty fuel is a notorious engine killer.

- Look Over the Hoses: Give your high-pressure and inlet hoses a quick once-over. You’re looking for any obvious cracks, bulges, or worn spots. A burst high-pressure hose isn't just an inconvenience; it’s a serious safety hazard for you and anyone nearby.

Following these simple steps protects the heart of your diesel pressure cleaner—the engine and the pump—from the most common and damaging issues.

Regular Checks for Long-Term Reliability

Beyond the daily pre-start, a few other regular checks will massively extend the life of your machine. You don't need to do these every day, but setting aside some time every month or so will pay you back big time in reliability.

One of the most overlooked parts is the nozzle. Over time, the sheer force of the water wears down the nozzle's orifice, making the opening larger. This causes a gradual but significant drop in pressure. If your machine just doesn't seem to be hitting as hard as it used to, a worn nozzle is often the culprit.

A well-maintained machine isn’t just about performance; it’s about efficiency. Keeping everything in top shape, from the engine to the pump, means you’re getting the most power out of every drop of fuel. It’s the same principle as keeping your other gear, like a forward plate compactor, running smoothly to get the job done right and on budget.

Your pump oil is another critical fluid to keep an eye on. Most high-quality pumps on diesel pressure cleaners have a handy sight glass. The oil should be clear and at the correct level. If it looks milky or cloudy, that's a dead giveaway that water has gotten in, and it needs to be changed immediately.

Your Simple Maintenance Checklist

To make things easy, here’s a straightforward schedule you can print out and stick on the workshop wall. It’s a handy schedule to keep your machine in top shape without needing a mechanic's degree.

| Check | Frequency | What to Look For |

|---|---|---|

| Engine & Pump Oil Levels | Before Every Use | Correct level on the dipstick/sight glass. |

| Fuel & Water Separator | Before Every Use | Any water or sediment in the bowl. Drain if needed. |

| Hoses & Fittings | Before Every Use | Cracks, leaks, bulges, or loose connections. |

| Nozzle Condition | Weekly | Obvious signs of wear or damage. Check for pressure drop. |

| Air Filter | Monthly | Buildup of dust and debris. Clean or replace as needed. |

| Change Engine Oil | Per Manual | Typically every 50-100 hours of operation. |

| Change Pump Oil | Per Manual | Usually every 300-500 hours or if it appears contaminated. |

Sticking to a simple routine like this is the single best thing you can do to protect your investment. It ensures your diesel pressure cleaner is always ready to perform, minimises downtime, and saves you from those expensive, catastrophic failures that always seem to happen on the most important jobs.

Using Your Pressure Cleaner Safely

Let's get one thing straight: a high-powered diesel pressure cleaner is a serious piece of equipment. With enough force to tear through timber or strip skin from bone, respecting its power isn’t just a good idea—it’s non-negotiable. This isn’t a safety lecture; it’s a list of practical, common-sense habits to make sure you, your crew, and your property get through the day in one piece.

Think of it this way: you wouldn't use a grinder without a guard or a chainsaw without checking the chain. A diesel pressure cleaner deserves that same level of respect. Getting complacent is the fastest way to cause serious injury or expensive damage.

Gearing Up for the Job

Before you even think about pulling that starter cord, you need the right gear. It's not about looking the part; it's about shielding yourself from high-pressure water and the debris it kicks up. Some of this gear is just as important as the tools you'd find in our general range of quality construction equipment, because safety underpins every successful job.

Your basic safety kit should always include:

- Safety Glasses or Goggles: This is non-negotiable. That high-pressure jet can flick a small stone or chip of concrete into your eye faster than you can blink.

- Steel-Toed Boots: Your feet are directly in the line of fire. A misplaced jet can easily slice through a regular boot, but a steel cap provides that critical layer of protection.

- Gloves: A decent pair of waterproof, grippy gloves helps you keep a firm hold on the wand and protects your hands from accidental blasts and general abrasion.

Smart Habits on the Job

Once you're kitted up, safety really comes down to how you handle the machine. The sheer force generated by diesel pressure cleaners creates a powerful kickback when you pull the trigger, and you need to be braced for it every single time.

Always hold the wand with two hands and plant your feet in a solid, balanced stance. This stops that initial kick from throwing you off balance or sending the spray somewhere you don't want it to go.

Never, ever point the nozzle at another person, even as a joke. The jet can inflict severe lacerations and injection injuries, where water is forced deep under the skin, causing serious and sometimes life-threatening damage. Treat it like a loaded firearm—always be aware of where it's pointing.

Knowing Your Nozzles

One of the biggest mistakes rookies make is grabbing the wrong nozzle for the job. Nozzles control the angle and intensity of the water jet, and picking the right one is crucial for both safety and getting the job done right.

Think of them like this:

- The Destroyer (0-degree red nozzle): This nozzle creates a single, pinpoint jet of extreme force. It's for blasting incredibly stubborn, isolated stains on hard surfaces like concrete. It's also extremely dangerous and can easily cut through wood, tyres, and skin. Use it with extreme caution and only when you absolutely have to.

- The Sweeper (25 or 40-degree green/white nozzles): These nozzles produce a wider fan spray. They're your go-to tools for general cleaning, washing down equipment, and clearing large areas. The force is spread out, making them much safer and more efficient for most tasks.

A good rule of thumb is to always start a job with a wider nozzle first. You can always switch to a more aggressive one if needed, but you can't undo the damage caused by starting with way too much force. By adopting these simple, practical habits, you ensure the only thing getting blasted is the grime.

Is a Diesel Pressure Cleaner a Smart Investment?

So, let's get down to brass tacks. Is a diesel pressure cleaner actually worth the hefty price tag? It's a serious piece of equipment and a significant outlay, so we need to be practical about whether it's the right move for you.

You really have to weigh up the undeniable pros against some very real cons. These machines are built for hard, daily graft, and that’s precisely where they start to pay for themselves.

Weighing the Pros and Cons

On one side of the scale, the advantages are pretty compelling. For anyone running a business where cleaning is a core part of the job, these are the factors that can turn a diesel unit into a genuine money-making asset.

- Unbeatable Power: Honestly, nothing else quite delivers the same combination of high pressure and high flow. This raw power means you clean faster and more effectively, which lets you squeeze more work into your day.

- Built for the Long Haul: Diesel engines are absolute workhorses, designed to run all day, every day. They tick over at lower revs, which means much less wear and tear on the engine. The result? A much longer working life compared to their petrol cousins.

- Work Anywhere, Anytime: You’re completely untethered. Whether you're out on a remote farm, a new construction site without power, or just the far corner of a massive workshop, you’ve got all the grunt you need.

On the flip side, you have to be realistic about the drawbacks. These aren’t necessarily deal-breakers, but you need to go in with your eyes open.

- The Upfront Cost: There’s no sugar-coating it—these machines cost a fair bit more than their petrol or electric counterparts.

- The Extra Weight: Diesel engines and the robust frames built around them add significant weight. They are heavy machines, no doubt about it, and take a bit of muscle to move around.

- The Noise: Even though they run at a lower RPM, large diesel engines still produce a considerable amount of noise.

Ultimately, the real question is this: will the machine make you money or save you time? If your business relies on heavy-duty cleaning, the efficiency, power, and sheer durability of a diesel will likely pay for the initial investment many times over. The productivity boost and longer service life make the numbers work.

This is a trend we're seeing across the board. The global pressure washer market is projected to grow to USD $7.10 billion by 2030. While that figure covers all types, the growth in the high-pressure segment—which is crucial for professional use here in Australia—points to a clear demand for more powerful, reliable gear. You can discover more about the pressure washer market trends to see how the demand for professional-grade equipment is shaping the industry.

If you’re just washing the ute on a Sunday afternoon, it’s massive overkill. But if your livelihood depends on time being money and grime being the enemy, a diesel pressure cleaner is one of the best investments you can make.

Frequently Asked Questions

When you're looking at serious bits of kit like diesel pressure cleaners, a few questions always come up. We get asked these all the time by guys on site, so here are the straight-up answers you need. No fluff, just the facts to help you make the right choice.

Can I Use a Diesel Cleaner for Small Jobs?

Technically, yes, but it’s a bit like using a bulldozer to weed your garden—it's total overkill. These machines are beasts; they're heavy, they're loud, and they're designed for big, demanding industrial work.

If you’re just washing the car or cleaning a small patio, a compact electric or a petrol model is a much better fit. You'll find them easier to handle, quieter to run, and far more economical for those smaller tasks. Save the diesel powerhouse for the jobs that actually need it.

What Is the Biggest Mistake People Make?

Without a doubt, the most common and costly mistake we see is neglecting basic maintenance. It happens all the time. People forget to do simple things like checking the engine oil, cleaning the fuel filter, or draining the pump properly before putting it away for a while.

Those few minutes spent on pre-start checks can literally save you thousands of dollars in repairs and weeks of frustrating downtime. Think of it as the best and cheapest insurance policy you can get for your investment.

Are Hot Water Diesel Pressure Cleaners Better?

For specific applications, they are absolutely phenomenal. If your work involves tackling thick grease, stubborn oil, or sanitising agricultural facilities, a hot water unit is in a league of its own. The heat melts away greasy buildup in a way cold water just can't, which often means you can use fewer chemicals and get the job done much faster.

That said, for general cleaning—like blasting mud off excavators or stripping back old concrete—a standard cold water machine has all the power you’ll need. Hot water units are a bigger investment, so it really boils down to whether you consistently face the kind of grime that only heat can beat.

How Long Should a Good Diesel Cleaner Last?

A well-built, commercial-grade diesel pressure cleaner is a long-term investment, not a disposable tool. With proper care and routine maintenance, you should expect to get thousands of hours of solid, reliable performance out of it.

Machines built with a quality engine and a durable belt-drive pump are designed to be workhorses, day in and day out. They are engineered to handle years of tough work, which is a world away from the consumer models that often fail under constant, heavy use.

Ready to invest in a machine that works as hard as you do? Machtig Equipment provides top-tier, reliable gear built for the toughest Aussie conditions. Check out our range of high-quality equipment today.

Article created using Outrank