- Sydney, Brisbane, Adelaide.

- Sales@MachtigEquipment.com.au

- 1300 037 319

A portable water pump isn't a one-size-fits-all tool; think of it like choosing the right spanner for a specific bolt. The best one is always the model built for the exact job you have in front of you, whether that’s clearing clean water from a flooded laundry or shifting muddy water from a trench.

Choosing a portable water pump isn't about grabbing the one with the biggest engine off the shelf. It’s about matching the right machine to the task at hand. Getting this wrong can mean anything from slow, frustrating work to a completely wrecked pump.

The good news is, it’s not that complicated once you know what you're looking for. It really all comes down to three key things: the quality of the water, how much of it you need to move (flow rate), and how far or high you need to move it (total head).

Let's get familiar with the main players in the portable water pump world. Each has a specific job it's designed to master.

Dewatering Pumps: These are your go-to for moving relatively clean water. Think emptying a swimming pool after a big storm, draining a hot water tank that’s burst, or clearing rainwater from a basement. They're built for high volume but can't handle much in the way of grit, sand, or leaves.

Trash Pumps: When the water is dirty, muddy, or full of debris, you need a trash pump. These are the absolute workhorses on construction sites and farms. A classic job for one of these is clearing out a muddy trench so you can lay pipes, or shifting water from a dam full of leaves and sludge to a stock trough. They have a tougher impeller and a wider intake designed to pass solids without clogging up.

High-Pressure Pumps: These pumps are less about volume and more about force. Instead of just moving water, they push it with enough pressure for tasks like back-country firefighting, running irrigation sprinklers over a large paddock, or even some heavy-duty pressure washing. They excel at moving water over long distances or up steep inclines.

A Quick Word of Advice: Never, ever try to use a dewatering pump for a trash pump's job. You'll spend more time unclogging it than working, and you'll likely destroy the impeller and seals in the process. It's a costly mistake I've seen happen more than once on a job site.

Before you can choose, you need to properly size up the job. A farmer shifting dam water to stock troughs has very different needs from a plumber trying to empty a muddy trench after a downpour.

Start by looking at the water source. Is it clear, or is it filled with sand, mud, and leaves? The answer immediately points you toward either a dewatering or a trash pump.

Next, consider the flow rate, measured in litres per minute (LPM). This is all about how fast you need the water moved. Draining a small puddle doesn't require a beast of a pump, but clearing out a flooded excavation before a concrete pour definitely does. For example, if you need to empty a 10,000-litre water tank in under an hour, you'll need a pump that can handle at least 170 LPM.

Finally, think about the total head. This isn't just how high you're pumping. It's the combination of the vertical lift from the water source (suction head) and the distance you're pushing it (discharge head), including any rise in elevation. A pump needs to overcome both gravity and friction, so moving water 100 metres across a flat paddock is a completely different challenge than pushing it 20 metres straight up a hill to a header tank.

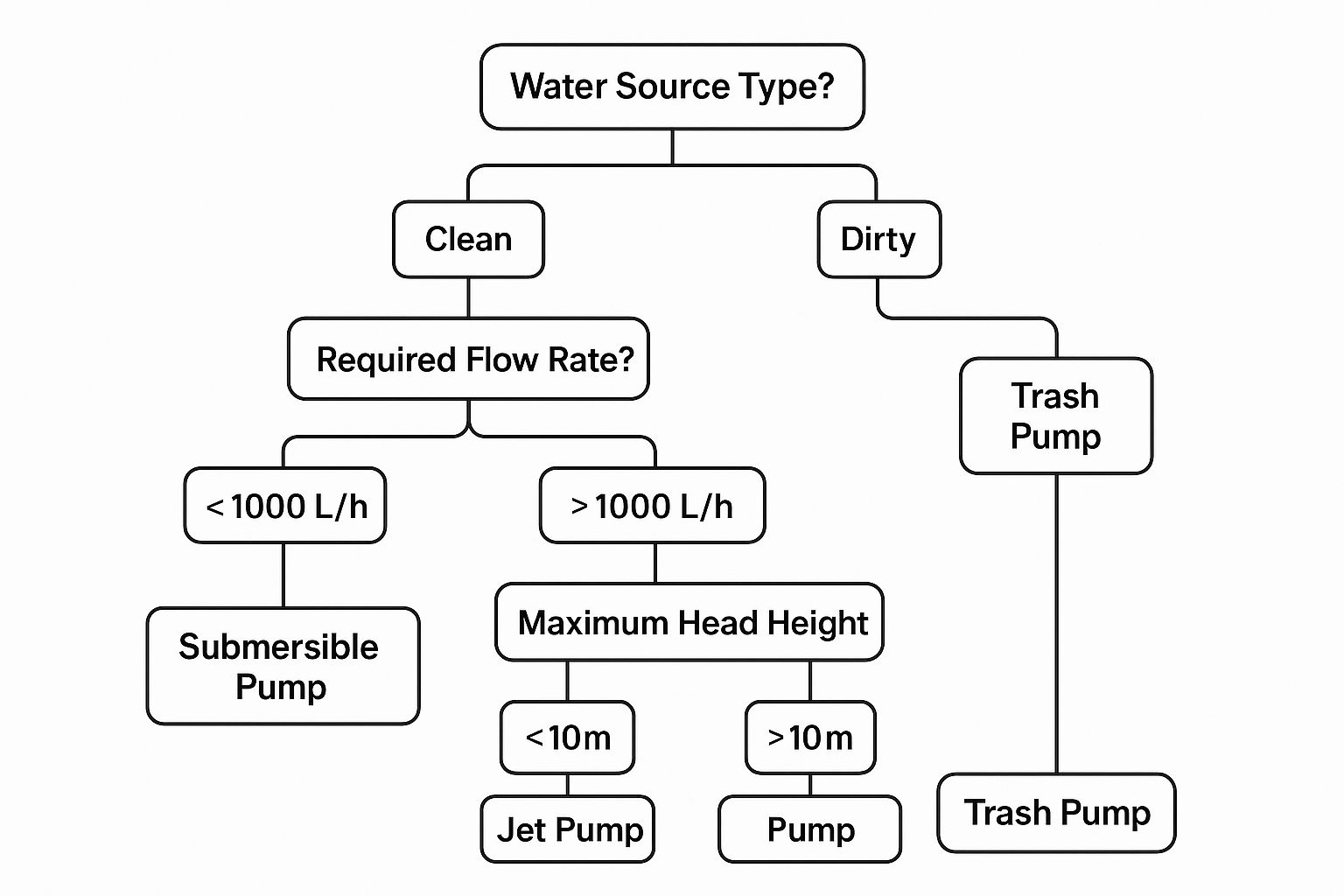

This decision tree gives you a great visual guide for figuring it all out.

As you can see, the specific demands of your job—from the type of water to the required pressure—will point you directly to the right pump, ensuring you have the power and capability you actually need.

To make it even clearer, here’s a quick-glance table to help you match the right pump type to your specific job.

| Pump Type | Best For (Water Quality) | Common Jobs | Key Feature |

|---|---|---|---|

| Dewatering Pump | Clean to slightly murky water | Emptying pools, flooded basements, draining tanks | High volume, fast flow |

| Trash Pump | Muddy, sandy water with debris | Draining trenches, construction dewatering, farm use | Passes solids without clogging |

| High-Pressure Pump | Mostly clean water | Irrigation, firefighting, dust suppression | Pushes water long distances or uphill |

This table should help you quickly narrow down your options based on what you're trying to achieve on site.

The demand for these practical tools is growing steadily, and for good reason. The Australian water pumps market, valued at around USD 162.5 million, is set to expand to nearly USD 232 million in the coming years. This growth really highlights just how essential efficient water management is across farming, construction, and mining. If you're interested in the numbers, you can find more details on these market trends in the full analysis from Research and Markets.

Getting your new portable water pump out of the box is the easy part. The real work—and what separates a reliable machine from a frustrating one—is in the setup. A proper installation is what guarantees your pump delivers when you’re knee-deep in mud and need it most.

It all starts with finding the right spot for the pump itself. This isn't just about convenience; it's about performance. You need ground that is as stable and level as possible. A pump vibrating away on an uneven surface is not only inefficient but can also cause serious wear and tear on the engine and frame over time.

Picture this: you're trying to drain a creek with a sloped, muddy bank. It’s tempting to just plonk the pump down on the angle. Don't. Take a minute to kick away some dirt or find a couple of flat rocks to create a level base. This simple act of stability prevents the pump from "walking" while it's running, which can put a huge amount of strain on the hoses and connections.

The goal is to get the pump as close to the water source as you can, both horizontally and vertically. The less distance the pump has to pull water up (what we call suction lift), the better it will perform. Every extra metre of height it has to suck water reduces its overall efficiency.

Once your pump is in a good spot, it's time to connect the hoses. This is where a lot of people go wrong, especially on the suction side. That suction hose, running from the water to the pump's inlet, needs to be completely airtight.

Any air leak, no matter how small, will kill your pump's performance. It will struggle to prime and will suck in air instead of water, leading to a weak, sputtering flow.

The discharge hose is more forgiving, but you still want to make sure it’s laid out without sharp kinks or twists. These will restrict flow and put unnecessary back-pressure on the pump.

A classic rookie mistake is using a cheap, flimsy suction hose. Always use a rigid, non-collapsible hose for the suction side. A standard lay-flat hose will just get sucked flat by the vacuum, and you’ll be pumping nothing but air.

You absolutely cannot run a portable water pump dry. Running it without water will overheat and destroy the mechanical seal in a matter of minutes. Before you even think about pulling that start cord, you must prime the pump.

Priming simply means filling the pump's casing (the volute) with water. This creates the vacuum needed to start drawing water up through the suction hose.

Now, your pump is ready to fire up. The initial setup might seem like a bit of a hassle, but taking these few extra minutes ensures your pump runs efficiently and reliably, whether you're on a building site or out on the farm. This same attention to detail applies to all heavy equipment—whether you're using a pump or checking the specs on powerful diesel pressure cleaners. Taking the time to do things right always pays off in the long run.

Running a portable water pump should be pretty straightforward, but a few smart habits can be the difference between a smooth job and a frustrating, costly breakdown. It's not just about yanking the starter cord and walking away. The real skill is in paying attention to how the machine runs—that’s how you'll catch small issues before they snowball into big ones.

This is all about the practical, day-to-day use of your pump. From the second you fire it up to the moment you shut it down, being mindful of its performance will save you a world of time and money. It's about getting the job done efficiently without taking shortcuts on the machine's health or your own safety.

Once your pump is primed and ready to go, the start-up itself is simple. But what you do next is what really counts. Don't just start it and forget it, especially not in the first few minutes. You need to stick around and just listen.

You'll quickly get to know the normal hum of your pump's engine and the sound of water gushing through it. Any new noise—a sudden rattle, a high-pitched whine, or a grinding sound—is a dead giveaway that something isn't right. It could be something as simple as a stone rattling around in the impeller housing or something more serious like a bearing on its way out. Catching it early is usually a cheap fix; ignoring it can mean a dead machine.

While it's running, keep an eye on the discharge hose. You're looking for a steady, strong stream of water. If the flow starts pulsing or gets noticeably weaker, that’s your cue that something’s up. This could be anything from a suction strainer that’s getting clogged with weeds to an air leak that’s developed in a hose fitting.

The single most destructive thing you can do to a portable water pump is run it dry. The mechanical seal inside relies on water for both lubrication and cooling. Without it, that seal can burn out in less than a minute, leading to major leaks and expensive repairs. Always make sure your water source is deep enough to last the entire job.

Whether you're running a petrol or electric pump, managing its power source and hoses correctly is absolutely vital for efficient operation. For petrol models, it's as simple as using fresh, clean fuel and checking the oil regularly. I’ve seen countless issues caused by stale fuel from last season clogging up carburettors, leading to all sorts of running problems.

The local market for water pumps is definitely growing, with more efficient models hitting the shelves. The Australian market was recently valued at AUD 263.4 million and is expected to expand quite a bit. It’s worth noting that electric-driven portable pumps are seeing their adoption grow at a CAGR of 4.4%, which points to a clear shift towards these convenient, no-fuss options. You can find more detail on these water pump market trends in Australia.

No matter the type, the way you lay out your discharge hose has a massive impact on performance. Every sharp bend or kink in that hose adds friction, which creates back-pressure that the pump has to fight against.

Hose Layout Tips:

Think of it just like a garden hose. When you bend it sharply, the water slows to a trickle. The exact same principle applies here, but the consequences are a strained engine and a job that takes twice as long. A few extra moments spent laying out your hoses properly really does pay off every single time.

A portable water pump is a true workhorse on any site, but even the toughest bit of gear needs a bit of care to keep it honest. Neglecting maintenance is the fastest way to turn a reliable tool into a frustrating piece of scrap metal right when you need it most.

Think of it like your ute—you wouldn't run it for thousands of kilometres without checking the oil, would you? The same principle applies here. Simple, preventative care is what saves you from costly downtime, unexpected repairs, and major headaches down the track.

This isn’t about becoming a master mechanic. It’s about a few basic checks that any practical person can handle with a handful of tools and a bit of common sense.

The engine is the heart of your portable water pump, and keeping it in top shape is your first priority. These are the quick, regular checks that should become second nature before a big job.

First up is the engine oil. Just like any small engine, it needs clean oil to run smoothly. Before you fire it up, pull out the dipstick, wipe it clean, and check the level. If it’s low, top it up. If the oil looks black and gritty, it’s time for a change. For most pumps running hard, changing the oil every 50 hours of use is a solid rule of thumb.

Next, have a look at the air filter. A clogged air filter is like trying to run a marathon while breathing through a straw—it chokes the engine of air, making it run rough and burn more fuel. Pop the cover off, pull out the foam or paper filter, and give it a tap to knock out the loose dust. If it’s really filthy, a foam filter can be washed in soapy water, dried, and re-oiled, while a paper one just needs to be replaced.

Finally, give the spark plug a quick inspection. A plug in good condition should have a light brown or greyish tan colour on the electrode. If it’s covered in black, sooty carbon, the engine is likely running too rich. If it's white and blistered, it could be running too hot. Cleaning it with a wire brush and checking the gap is good practice, but for the few dollars they cost, simply replacing it every 100 hours or so is cheap insurance.

The engine might provide the power, but the pump end does all the hard work of moving water. This is where you’ll find problems after a day of pumping muddy water from a trench or a dam.

The most important job is cleaning out the pump housing and impeller. After a job, especially with dirty water, disconnect the hoses and flush the casing with clean water. This gets rid of any sand, grit, or mud that can settle inside, which can cause corrosion or jam the impeller next time you start it.

While you're at it, it’s a good idea to remove the inspection plate on the pump housing to check the impeller itself. Look for a few key things:

A five-minute flush with a hose at the end of the day can add years to the life of your pump's seals and impeller. It’s the single best habit you can get into, especially if you’re working with anything other than perfectly clean water.

If you know your pump is going to be sitting in the shed for a few months over winter, don’t just put it away wet. Proper storage prevents a whole host of problems like seized parts, fuel issues, and dried-out seals.

The biggest enemy of a stored petrol engine is stale fuel. Modern petrol goes off, leaving gummy deposits that will clog up your carburettor. Either run the pump completely dry of fuel or, even better, add a quality fuel stabiliser to a full tank and run the engine for a few minutes to circulate it through the system.

For the pump itself, make sure you drain all the water out of the casing and hoses. Leaving water inside can lead to corrosion, and in colder climates, it can freeze and crack the housing. Flushing it with clean water and letting it dry out completely is the best approach. This prevents the seals from getting stuck or drying out while it's not in use.

This level of routine care is especially vital in sectors like agriculture and construction. The agricultural and mining industries are the biggest users of these pumps, with farming alone driving a huge portion of demand. As infrastructure projects and rural water access continue to expand, the need for reliable equipment that can handle tough conditions is only growing. Keeping your gear in top nick ensures you're ready for any job. You can get more details on how these industries are shaping the market by exploring water pump procurement trends in Australia.

There’s nothing worse than being in the middle of a job when your pump decides to pack it in. When your portable water pump gives you grief, you need a fix, and you need it fast. Think of this section as your on-the-spot guide for figuring out what’s wrong and getting it sorted right there and then.

Most of the time, the fix is something you can handle with a few basic tools and a bit of know-how. This means you can get back to work quickly, saving yourself half a day and a pocketful of cash on a trip to the repair shop.

This is the classic headache. You can hear the engine roaring away, but not a single drop is coming out of the discharge hose. Nine times out of ten, the problem is on the suction side of the pump.

Before you even think about tearing the engine apart, just run through these simple checks. More often than not, one of these will be the culprit.

Did you lose your prime? It’s an easy one to forget when you’re in a rush. If the pump casing isn't full of water, it can't create the vacuum it needs to start pulling water. Just switch off the engine, pop open the priming port, and top it right up until it’s completely full.

Is there an air leak in the suction hose? Even a tiny pinhole or a loose fitting will let the pump suck air instead of water. Check that the hose itself has no cracks or splits, and make sure the couplings are wrenched down tight with their rubber gaskets in good nick.

Is the suction strainer blocked? That strainer, or foot valve, at the end of your suction hose loves to get clogged with leaves, mud, and whatever else is in the water. Pull the hose out and give the strainer a proper clean.

Is your suction height too high? Most portable pumps have a maximum suction lift of around 7-8 metres. If you’ve positioned the pump too high above the water source, it just won’t have the grunt to pull the water up. Try moving the pump closer to the water.

So, the pump is working, but the flow is weak or sputtering? That’s a clear sign that something is restricting the water's path. This kills your efficiency and puts unnecessary strain on the engine.

A sudden drop in performance is your machine telling you something is wrong. Don't just push on and hope it fixes itself. A weak flow can quickly turn into no flow at all—or worse, cause serious damage to the pump's internals.

Start with the most obvious culprits first.

Check for a kinked or blocked discharge hose. Walk the full length of your discharge hose. A simple kink can easily slash your flow rate in half. While you're at it, check the end of the hose to make sure it isn't buried in mud or otherwise blocked off.

You might have a clogged impeller. If you’re pumping water with a fair bit of debris, it’s pretty common for small stones, stringy weeds, or other gunk to get lodged inside the pump housing and jam the impeller. After shutting down the engine, you can usually take off an inspection plate on the front of the pump casing to get in there and clean it out.

Sometimes the problem isn't with the pump end at all, but with the engine that powers it. A few simple checks here can save you a lot of frustration.

Here’s a quick chart for the most frequent engine headaches you'll face on site. It’s designed to help you get from problem to solution in minutes, not hours.

| The Problem | Likely Cause | What to Do About It |

|---|---|---|

| Engine Won't Start | No fuel, old fuel, or a fouled spark plug. | Check the fuel tank first. If there's fuel, make sure it’s fresh. Stale petrol can clog the carburettor. If that’s not it, check the spark plug—clean it or replace it if it looks sooty or worn. |

| Engine Runs Rough | Clogged air filter or water in the fuel. | A dirty air filter will choke the engine, causing it to sputter. Clean or replace it. If you suspect water got in the fuel, you'll need to drain the tank and the carburettor bowl, then refill with fresh petrol. |

While these straightforward fixes cover the vast majority of issues you’ll run into, sometimes you need a bit more detail. For more advanced guides and tips on keeping all your site equipment in top shape, feel free to check out our other articles on the Machtig Equipment blog.

Even with the best guides, you're bound to have a few questions when it comes to picking and using a portable water pump. Here are some of the most common ones we hear from blokes on the job. We'll give you clear, practical answers to help you get the best performance from your gear.

This is a big one, and getting it wrong is a costly mistake. A dewatering pump is built for shifting relatively clean water—think emptying a swimming pool or a flooded room. It moves a lot of water fast but can't handle much more than a little bit of grit.

A trash pump, on the other hand, is the heavy-hitter you need for the tough stuff. It has a beefier impeller and wider intake designed to pass through mud, leaves, and even small stones without getting clogged. If you're pumping from a ditch, dam, or muddy construction site, you absolutely need a trash pump. Trying to use a dewatering pump for that job will just lead to constant blockages and a wrecked machine.

Sizing a pump properly comes down to two main things: flow rate and total head. Don't just grab the biggest one you can find; you might be paying for power you don't need.

Flow Rate: This is how much water you need to move, measured in litres per minute (LPM). Are you draining a small trench or dewatering an entire foundation? A rough estimate here is your starting point.

Total Head: This is the total height the pump has to move the water. You calculate this by adding the vertical distance from the water source up to the pump (suction lift) and the vertical distance from the pump up to where the water is being discharged (discharge head).

A good rule of thumb is to choose a pump that slightly exceeds your calculated needs. This ensures the pump isn't running flat-out all the time, which reduces wear and tear and extends its life.

You need to be very careful with this one. While using a long discharge hose is usually fine, the length of the suction hose is critical to your pump's performance. Most portable pumps have a maximum suction lift of around 7 to 8 metres straight up.

Every extra metre of suction hose adds friction, making it harder for the pump to prime and pull water. A longer hose also increases the risk of air leaks, which will kill your performance. It's always better to position the pump as close to the water as possible and use a longer discharge hose to get the water where it needs to go.

For more in-depth advice on equipment best practices, be sure to explore the helpful articles on our Machtig Equipment blog.

When you need reliable equipment that won’t let you down, Machtig Equipment has the gear built for the job. Check out our range of high-quality construction and agricultural equipment at https://www.machtigequipment.com.au.

Article created using Outrank